Porsche Fueling: EFI vs Carburetor, CIS and MFI

Porsche air-cooled engine bays have forever had a sort of “industrial” look to them. I am not saying this is a bad thing, but there is a reason Ferraris have a big window on their mid-engine platforms. The engines are pieces of art. Plain and simple. Porsche engines are industrial in the sense that they perform and have the rugged way about them. They don’t necessarily look pretty. Their purpose is to perform and that’s what they do. Part of the reason the Porsche engines have never looked beautiful is due to their way of fuel injection. Whether it be the raw 2.7RS MFI (mechanical fuel injection), the classic CIS (continuous injection system), Weber/PMO carburetors or even the EFI system used in the mid 80s-late 90s. All of these methods of injection from Porsche are just not the prettiest…that’s a fact, not opinion! (just kidding). Not only are they “industrial”, but the older methods of injection are just not as precise as EFI. Meaning your engine is wearing out quicker. Ill break down every method of fuel injection below with some basic detail.

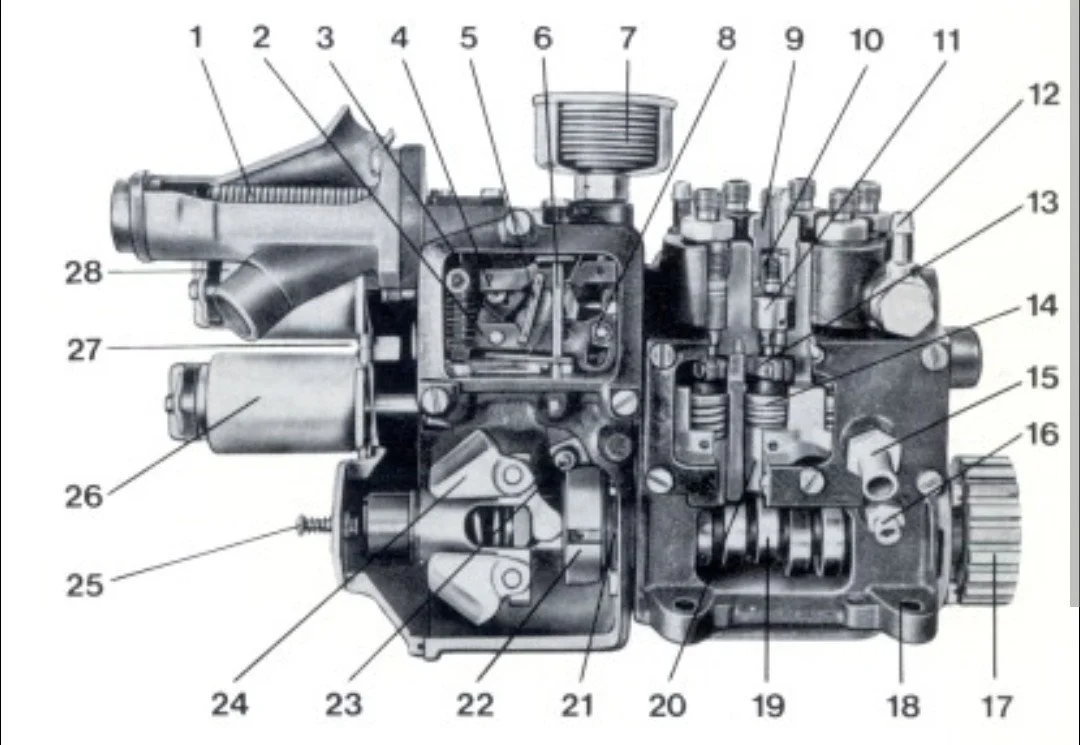

1) The MFI system did its job just fine. Mind you, it is a miniature engine on top of your engine. The injection box had its own "cam”, pistons springs and diaphragms. Driven off a belt powered by your engine’s camshaft. AND it just sits on top of your engine like a lump. The fuel was delivered by these metal lines spidering across your engine. Getting this to run correctly was a matter of throttle linkage placement (punching various holes and literally changing the placement of the linkage) and a small flathead screwdriver. The internals would wear down and require your pump to be rebuilt. It even stole oil from the engine itself to lubricate the internals! The fuel mixture was always something of concern with this pump. Several factors were at play to keep the engine running happy. You will see what I mean below. The word industrial suits the way this works perfectly.

A good side view example of this MFI pump

That is basically an engine

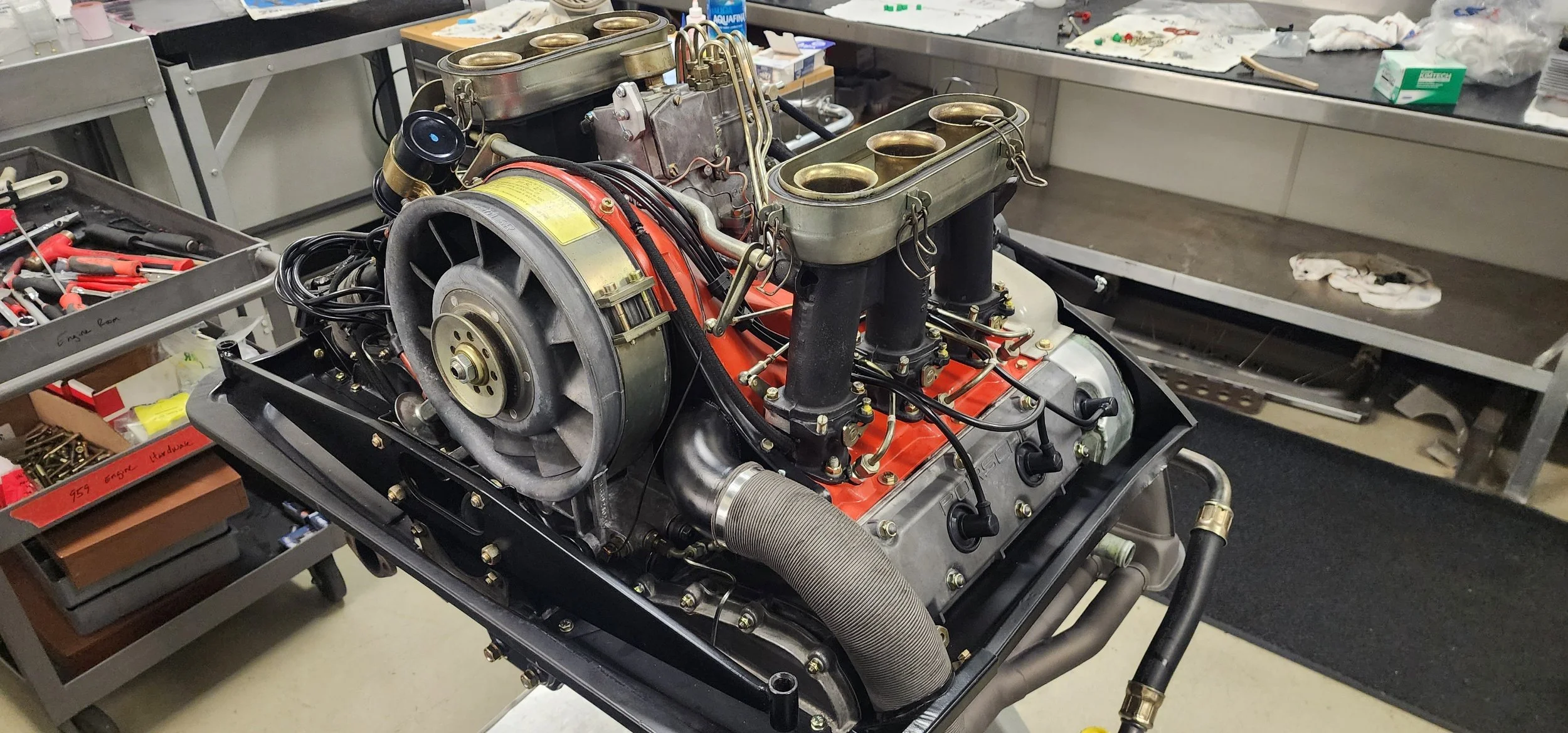

This is a 2.7 engine

Not the worst looking injection system. The lines, linkages and fuel pump just make it crowded still

2) Up next, we have the CIS System from Bosch. The continuous injection system was more sophisticated than the MFI unit. Still having some mechanical properties involved, the CIS system went a step further with a few variants using electronics. It was a system based on electrical and mechanical pressure control to deliver fuel properly. A “warm up regulator” was a key part in this. Varying pressure based on temperature. There was a metal pin you can punch down(literally) to adjust pressure. Then there was the Fuel Distributor (FD). A chunk of cast iron (later aluminum) to meter and distribute the fuel to each cylinder. Inside the FD was a metal diaphragm, springs, filters, shims and slide valves. ALOT of mechanical moving components in one hunk of metal. AND it sat right on top of your “airbox”. This was by far the ugliest thing put into an air-cooled engine bay. Diagnosing the CIS system was like diagnosing an electrical circuit with fuel inside of it. It was not the easiest by any means, but I have to admit, the help you can find online these days is nuts. Kudos to all those dedicating their time to keeping the classics alive in the OE sense. Seriously. I’ve failed to mention the other components like the fuel accumulator, the auxiliary air regulator or valve (AAR or AAV), the cold start injection and the specific fuel pumps. But I think my point is made. CIS is complicated for a fuel injection system. The tune-ups on CIS require a decent amount of time for set up and diagnosis as well. There are several mechanical parts here that can wear out and change your overall AFR. Below will be some examples of CIS parts and how it looks.

A sad warm up regulator

This is another issue with the mechanical parts in the system, corrosion and debris build up within the metals - causing clogs, parts seizing up and more.

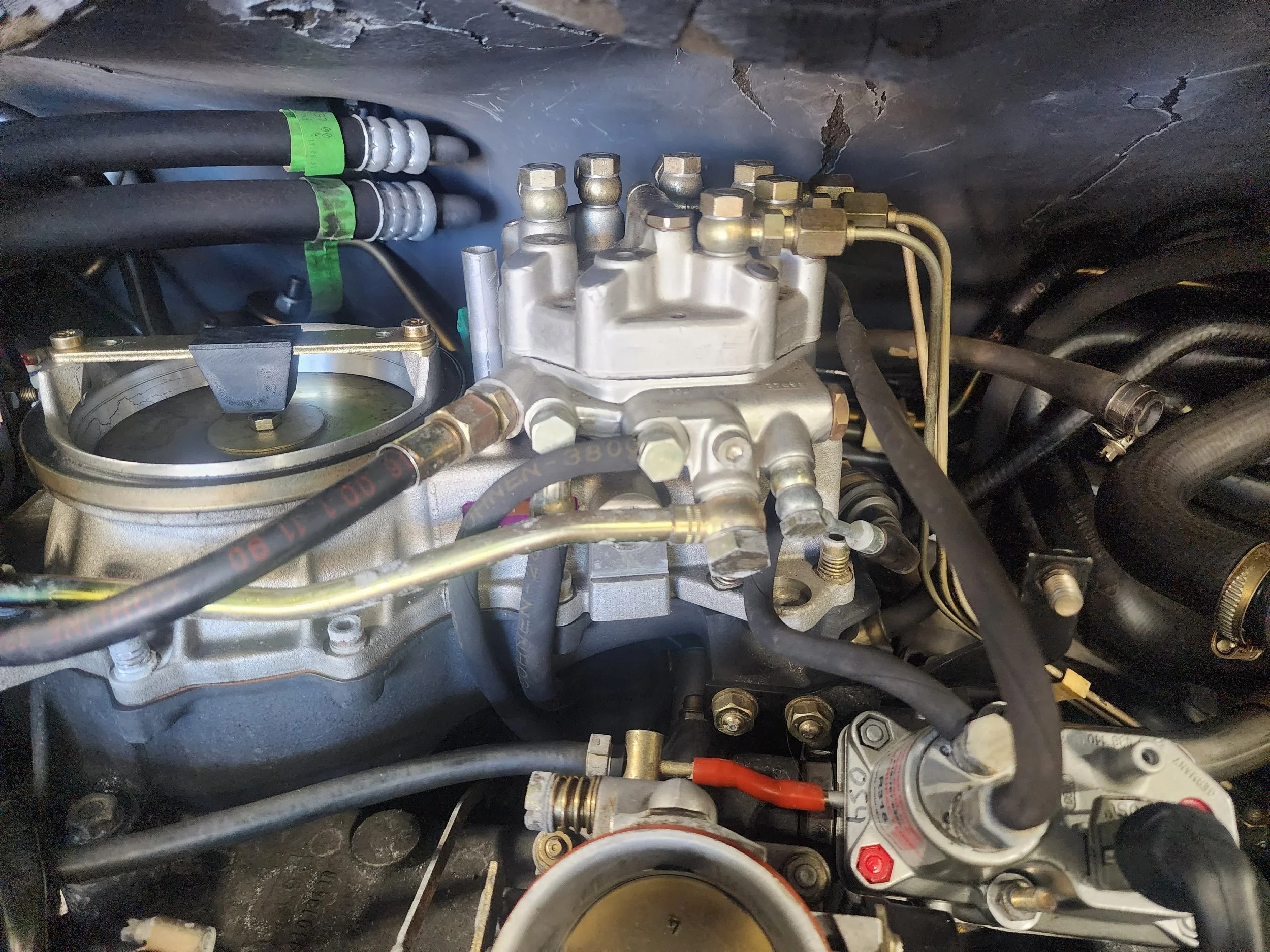

A 964 Turbo Fuel Distributor

This is the monster. The ugly, bulky hunk of metal that distributes and controls fuel delivery. Notice the sound pad above it is old and falling apart. Guess what is in the way of replacing the sound pad easily. Yep. The FD. I also didn’t mention the amount of fuel lines that will break down over time. It is a decent amount of lines to think about when buying an air-cooled!

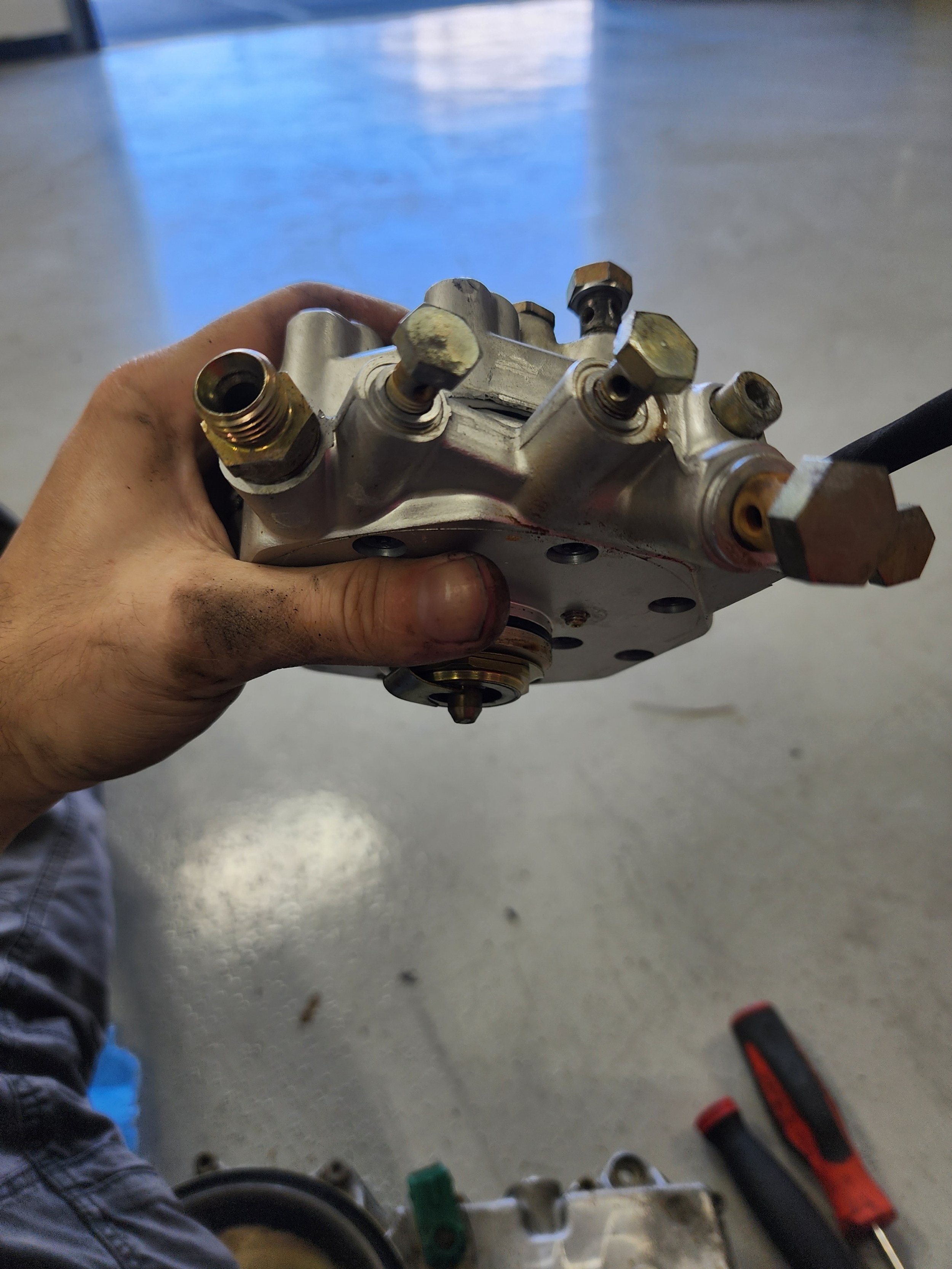

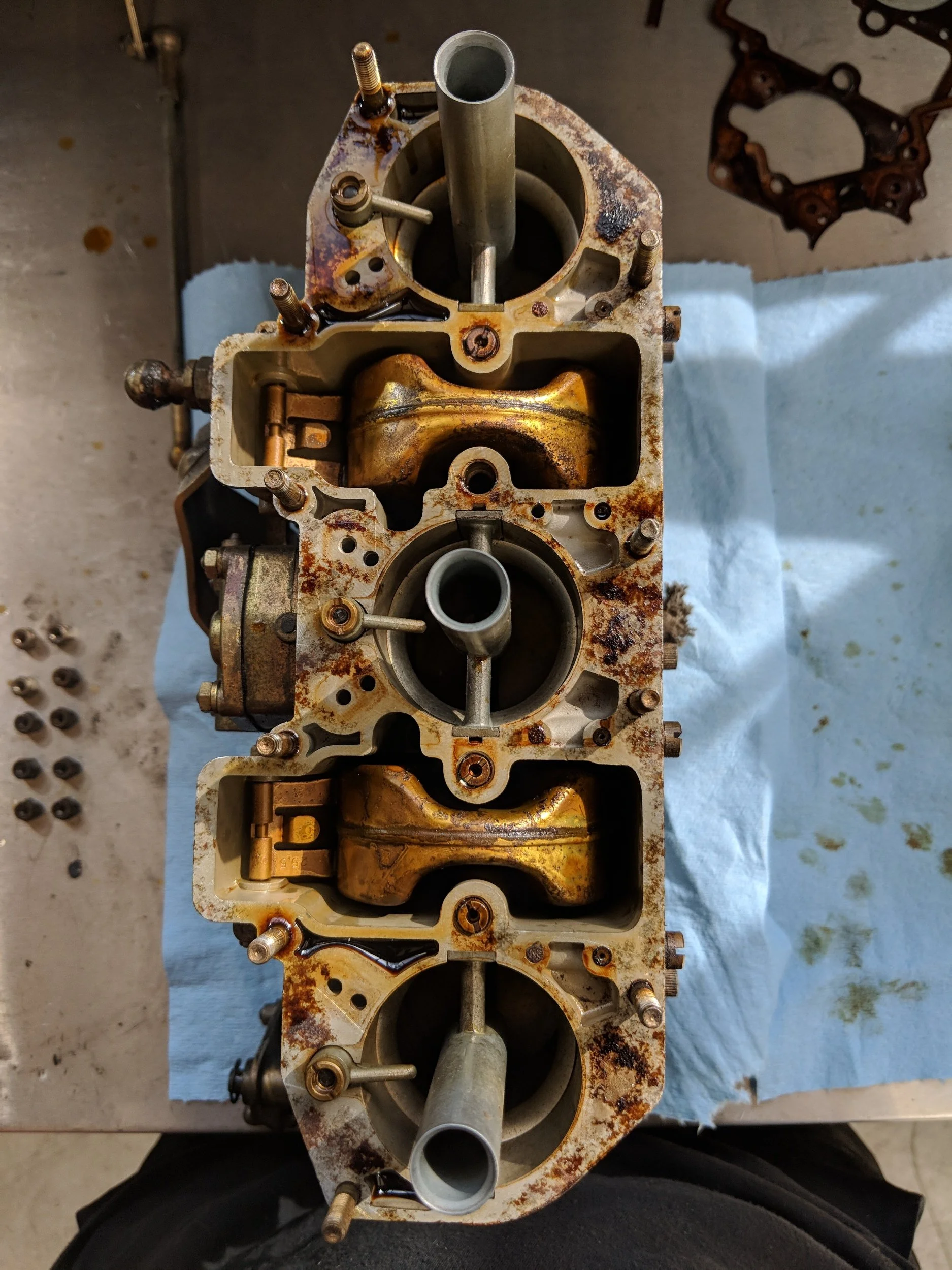

A Fuel distributor in pieces

Here are the guts of the FD. Lots of little bits

Here is the 964 Turbo FD out of the engine bay

It’s a beauty ain’t it?

3) Next we have the carburetors. My personal favorite if you are not going with EFI on a Porsche. Carbs are what I like to call “dirty” injection. It feels sloppy and uncontrolled even though the engineering behind carburetors is pretty neat. I’ve worked with many carburetors. From Alfas, classic minis, Porsche 356s, Ferrari 365s/250s and so on. I find the noise from a carburetor on these sports cars is something that everyone should experience. And the smell, oh man. Hands down, the best carburetor smells come from classic Ferraris. But overall carbs have a distinct smell that is what makes me call them “dirty”. Carbs are ran by well-designed pointed screws, thin channels, tiny little jets, floats, venturis and more. It really is cool, old tech that is still fascinating in the 21st century. But there are still issues here. If you let fuel sit for 6 minutes too long in carbs, they leak. If you let fuel sit for 7 minutes too long, they clog up. If you drive your car up Pikes Peak, your carbs run out of breath at 2000ft elevation before even thinking about the top of the mountain. Of course, I’m exaggerating some. But you get the point. Not to mention, carbs generally run rich as a factory setting. It’s just the nature of having a “fixed” injection set up. This means that once again, your cylinders are wearing out quicker, your oil is breaking down quicker and anything related to oil or needing oil is breaking down quicker. Quicker than if you had EFI that is. But boy oh boy do carbs sounds phenomenal! Here are some Porsche Webers for you to look at.

Weber IDA carbs

Out of all the non-efi options. These are the greatest eye candy

The gunk I mentioned

Gunk is bad, mkay?

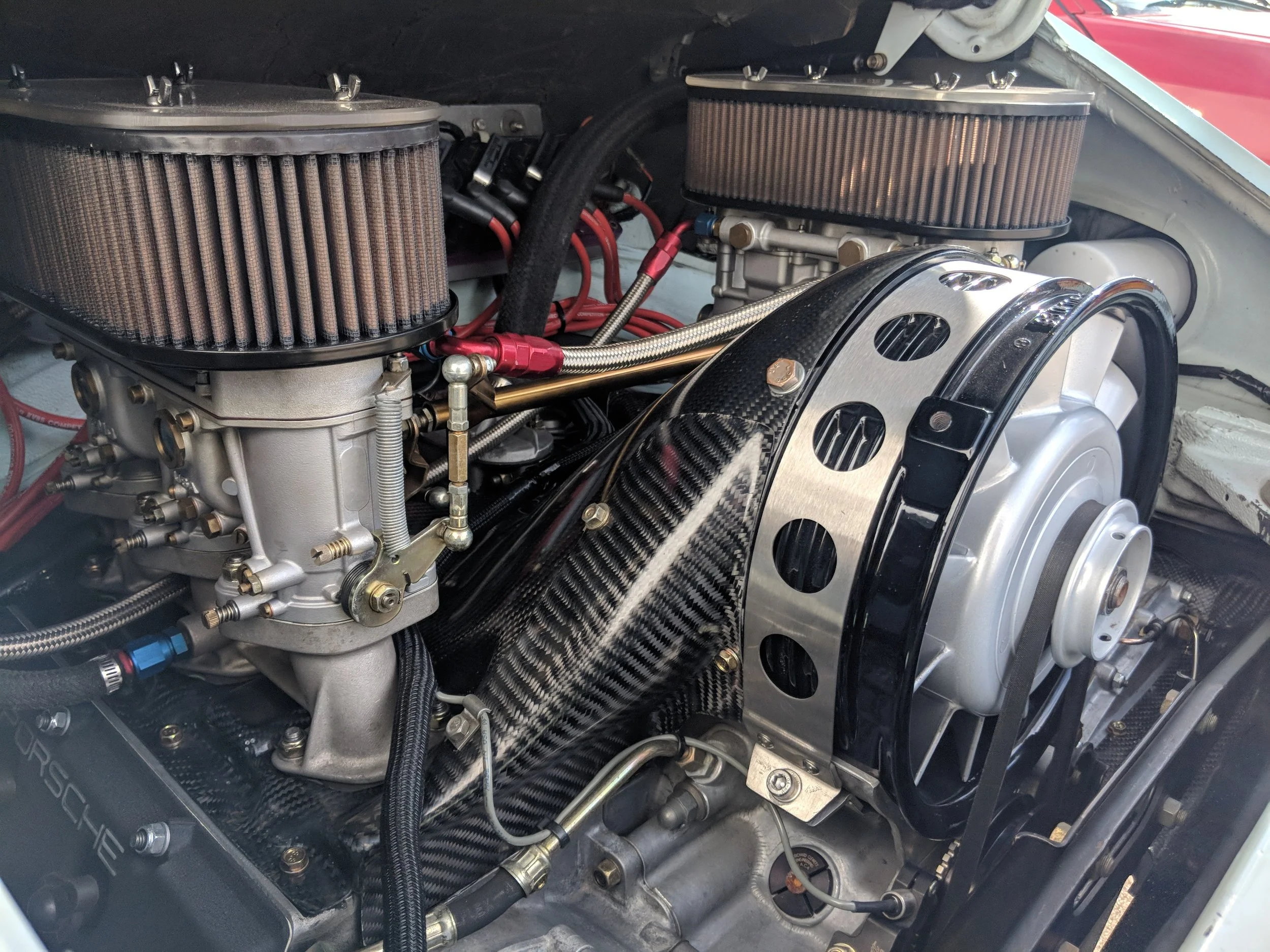

A great example of why the carbs are the best looking

The 12-point distributor adds some spice

Some PMO Carbs

These are modern replacements to the Weber IDAs. These are worth the money if considering the carb conversion!

Another clean carb set up

4) Finally, we are at EFI or electronic fuel injection. Porsche’s engines were kitted with EFI from the mid 80s and on. The control and precision that comes with electronic fuel injection is leagues better than anything previously talked about. The “problem” with the OE EFI solutions was that it still was nothing to drool over. It worked great and reliably - functionality was all there. People came out with tuning chips for the ECUs to cope with certain engine mods and life was good. But what a mess of an engine bay still! A prime example is the 993 C2. You can barely see the engine at all. This is because of the emissions regulations. Porsche had to meet strict standards to keep this robust engine design going for as long as it did. In order to do that it meant there had to be lines, hoses, air pumps, valves and wires all at use in the engine bay to clutter it up. But still, this fully electronic control of the fuel gave the engines a much healthier life span. Sometimes, when done correctly, with direct injection involved (but we won’t touch on DI yet).

Now to get on a bit, EFI is still being improved upon. Alot of the improvements are seen in the aftermarket world with the likes of Motec, Haltech, Life Racing, ECUMasters, and so on. The aftermarket world is saving EFI and making it easier and easier to put the full control of your engine into your (the consumer’s) hands. And with that comes some good-looking intake options for the Porsche air-cooleds. ITBs (individual throttle bodies) aren’t a new thing at all, but they are the saving grace for the Porsche air-cooled engine bay. There are many brand options and a few styles to choose from for a nice ITB kit on your Porsche air-cooled. I have my own favorites based on design and practicality. Some are outdated in the sense that they still use linkages to manage the throttle butterflies. They think they’re in the 90s still. Some have varying intake runner lengths or angles that don’t seem to be the most efficient. But there are a couple great options out there - (Adapt Motorsport is a great option) The engines will really wake up with a good ECU and ITB combination. No internal upgrades necessary to feel a change. Just fuel and air. More power, more precise fuel control and alot more fun. It is without a doubt that an EFI conversion or upgrade with throttle bodies is one of the more fun things you can do to your air-cooled. Below Ill post some good examples of kits you can find out there…eITB kits for the win.

Adapt Motorsport’s eITB kit

Nice and tidy, no linkages in sight, drive motors are hidden in the back of your engine bay

Throttle for the eITB kit

The transient throttle tuning has never been better

Trumpets or GT3 style plenum

See Adapt’s website for more information

Installed e-throttle

Can you even tell the difference?

The accessories to the whole package can make or break the ease of install and tuning. Its a big deal to see the quality in every direction