The Porsche 959SC Engine

This is meant to give a little bit of insight into the famous 959SC engine

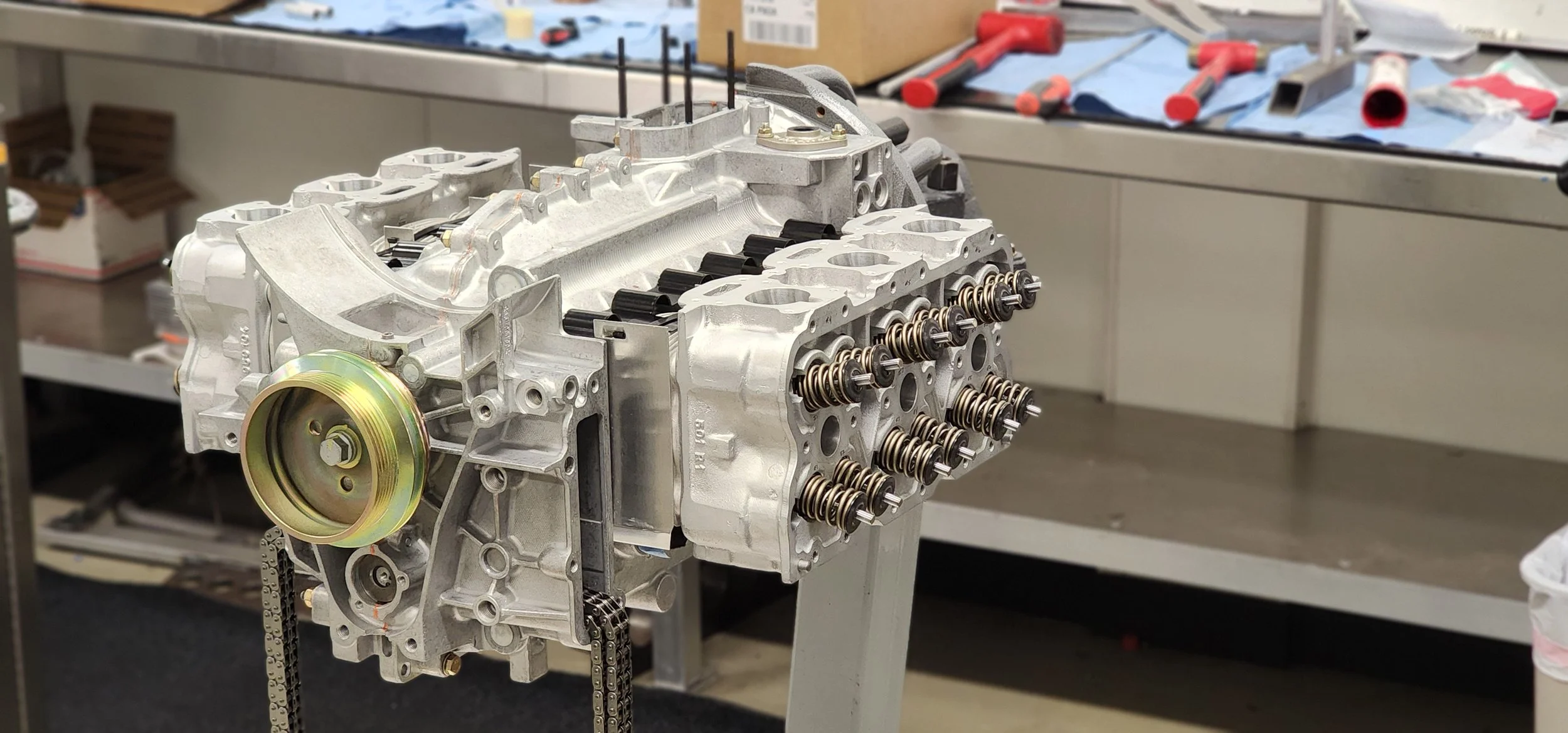

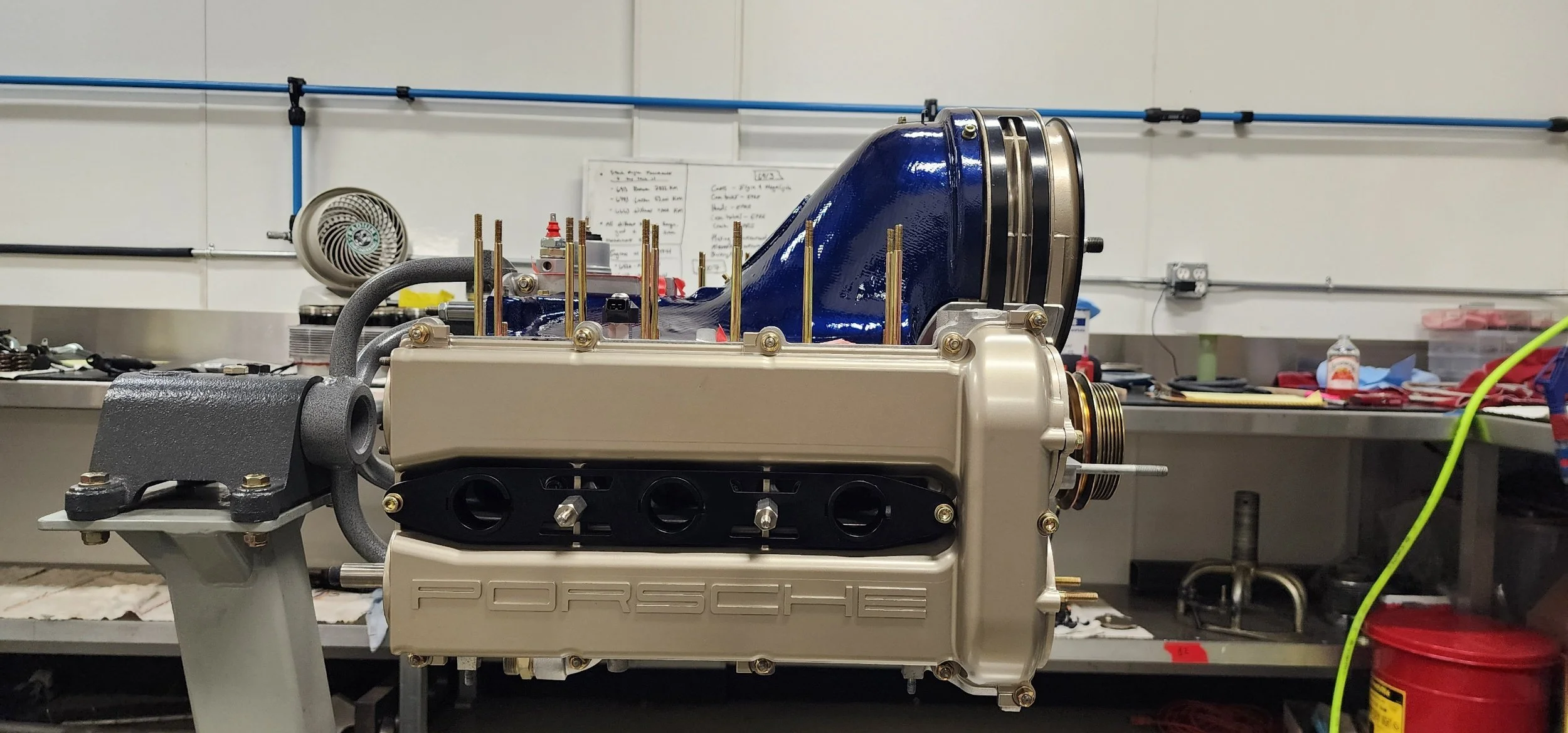

The engine strongly resembles your classic air-cooled 911 engine. Up until the heads. The heads are a glimpse into Porsche’s future with the water-cooled 911s, Boxsters and Caymans. The heads have ports for coolant both on the intake and exhaust side, creating the need for a coolant “manifold” on both ends as well. You’ll see this pictured below. These heads are also special in the sense that they have 4 valves per cylinder. Making this a dual overhead cam engine.

The chain housing is also a glimpse into the future of the 911 as well. The gaskets used for the chain tensioners can be replaced by 996 part numbers. The chain housings come from the factory made from a magnesium alloy and became very porous over-time. So, one of the upgrades to the 959SC engine was billet chain housings. This created a much tighter seal between the engine case and the cam tower that bolts to the heads.

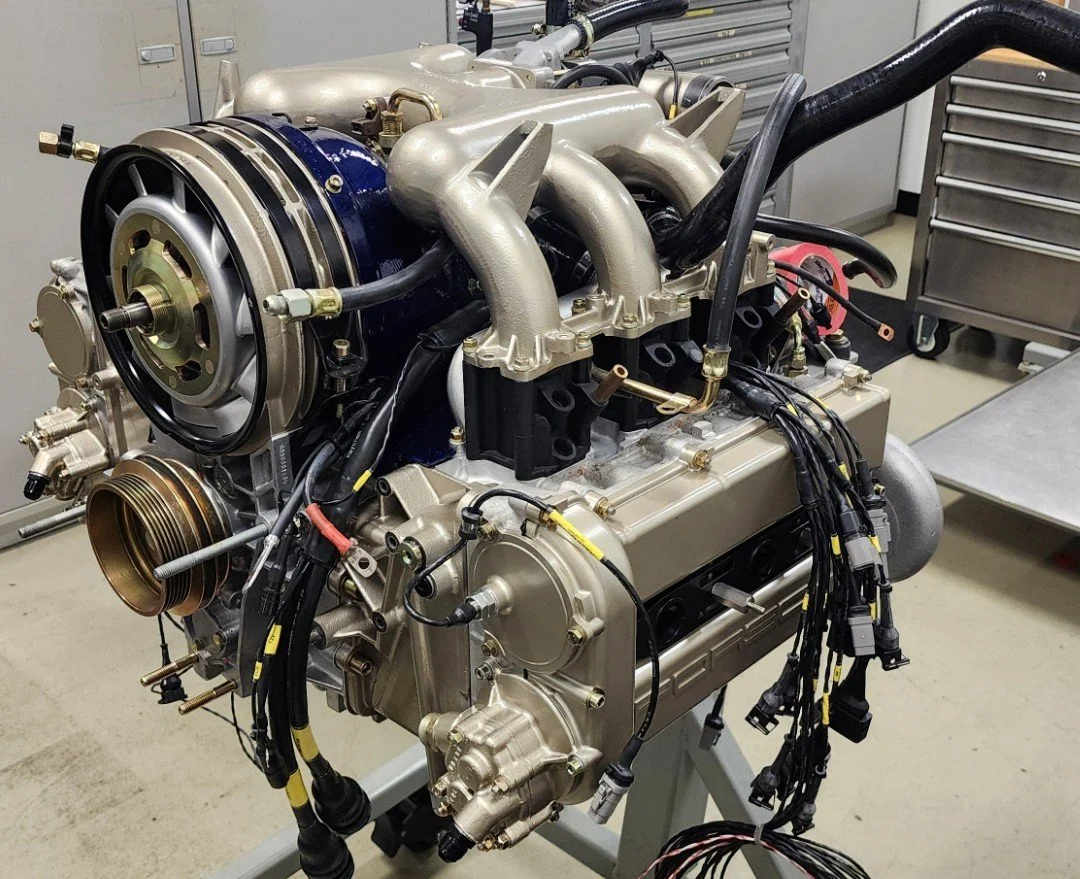

Another difference from the air-cooled engine is the factory sequential turbo set up. The 959SC has an modern Borgwarner efr twin turbo set up with each turbo powering its respective bank of 3 cylinders. To supply the oil through these turbos, there are exhaust cam-driven scavenge pumps that came made of magnesium originally and have been upgraded to a replicated billet housing. The turbos are mounted via a factory turbo support bracket that bolts to the front engine brace.

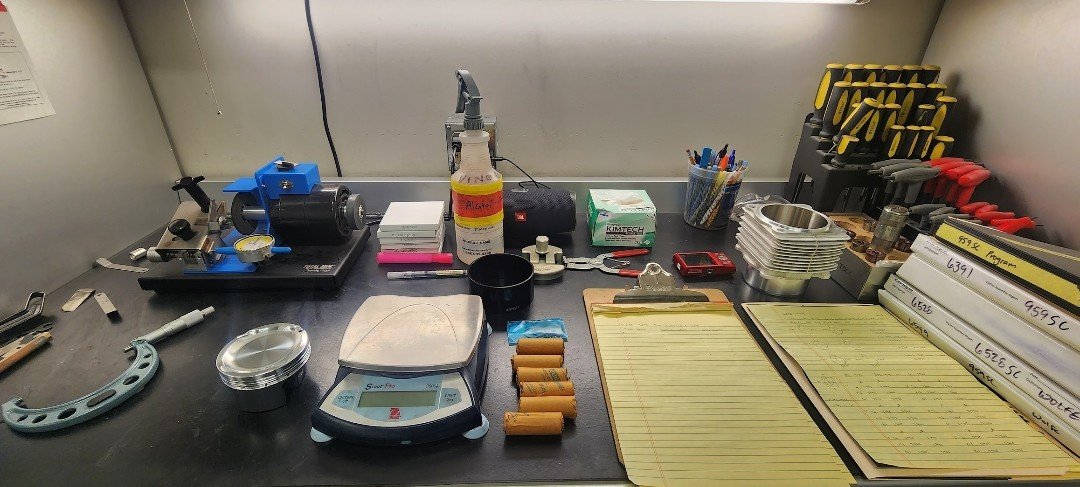

Internally, the 959SC is mostly stock. The engine is built to hold power and is very similar to the Porsche 956 Race engine. All that we changed were the rods, pistons and valve train components. This included a serious deep dive of tedious measurements and blueprinting to replicate the power in each engine. The cam lifters were originally hydraulic and were converted to a solid lifter set up with the help of the legendary Ed Pink. I came into the picture after this had already been altered, but I believe hydraulic is still the right answer here after some research on new “off-the-shelf” lifters I discovered online. Ed was just giving a good and reliable solution to the 30-year-old lifters that he knew 100% would work for our power range. We used Pankl connecting rods and CP pistons for out hardware upgrades underneath the head. NPR piston rings are the answer for the new Mahle cylinders that we had made as well.

Water pumps are found on the rear of the engine and were also driven by the exhaust cam (the exhaust cams are putting in alot of work here). The pumps were satisfactory besides the impeller. A new billet impeller was made to replace this.

Accessories on the 959SC engine included new Injector Dynamics injectors, a RaceGrade engine harness, Motec ECU control, Borgwarner EFR turbos, Cylinder head cnc porting with larger valves, uprated custom valve train, Bosch coil on plug ignition, Radium fuel pressure regulator and damper, CP pistons, Pankl Rods, Coated main oil pump internals and a few more I’m sure I’m missing.

Overall, the engine took between 120-150 hours to build to completion. At times I would have 2 or 3 lined up in the engine room at once like an assembly line. Such a cool sight to see. I will forever be grateful to have worked on these very special Porsche engines. Hope you enjoy the media!

The upper coolant manifold is pictured here in its bare-bones state

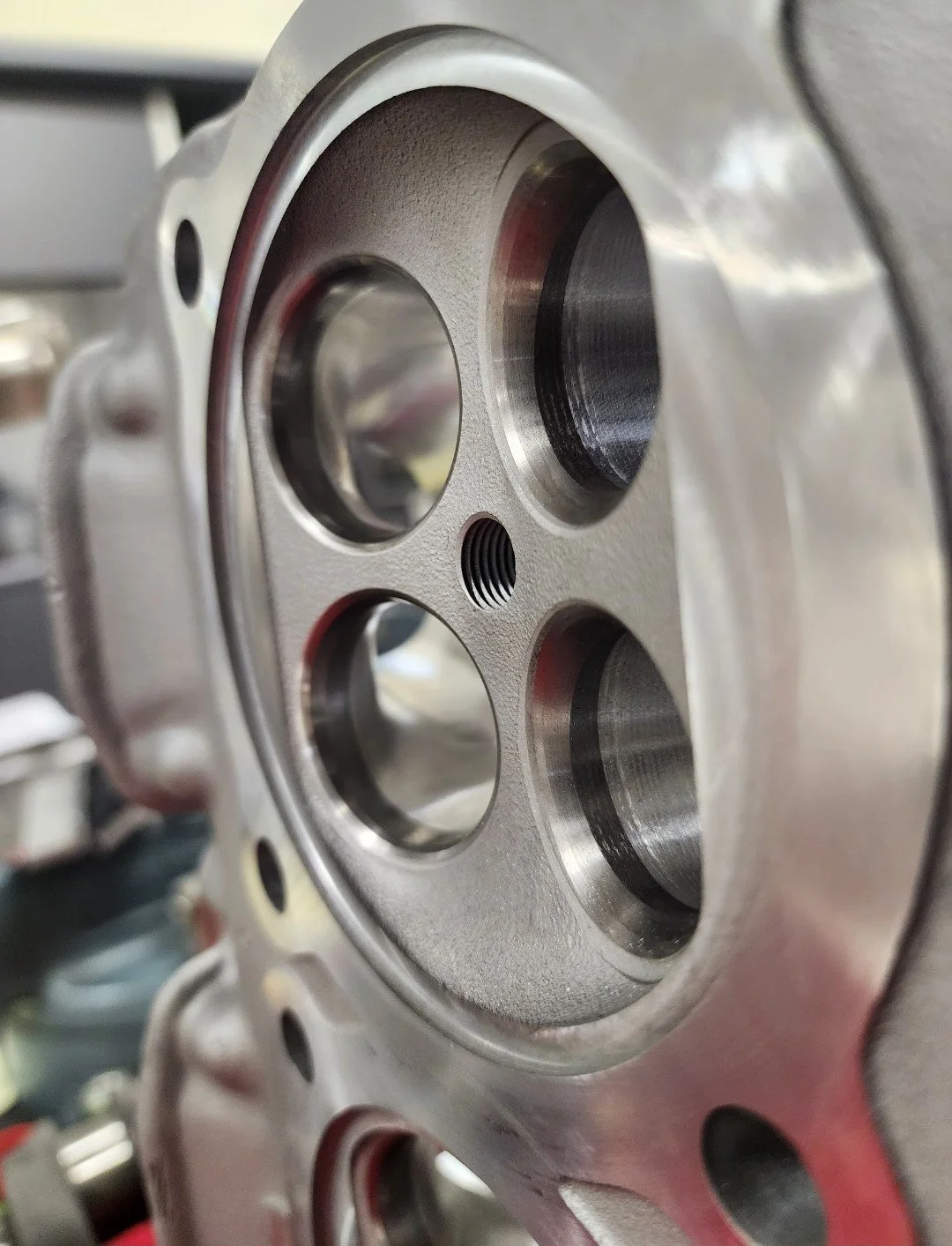

a line of fresh cylinders heads ready for assembly, machining done on every surface

Good view of the valves and bare cylinder head

New billet cam covers to stop the misc. oil leaks from the OE magnesium ones

In the middle of “assembly line” mode

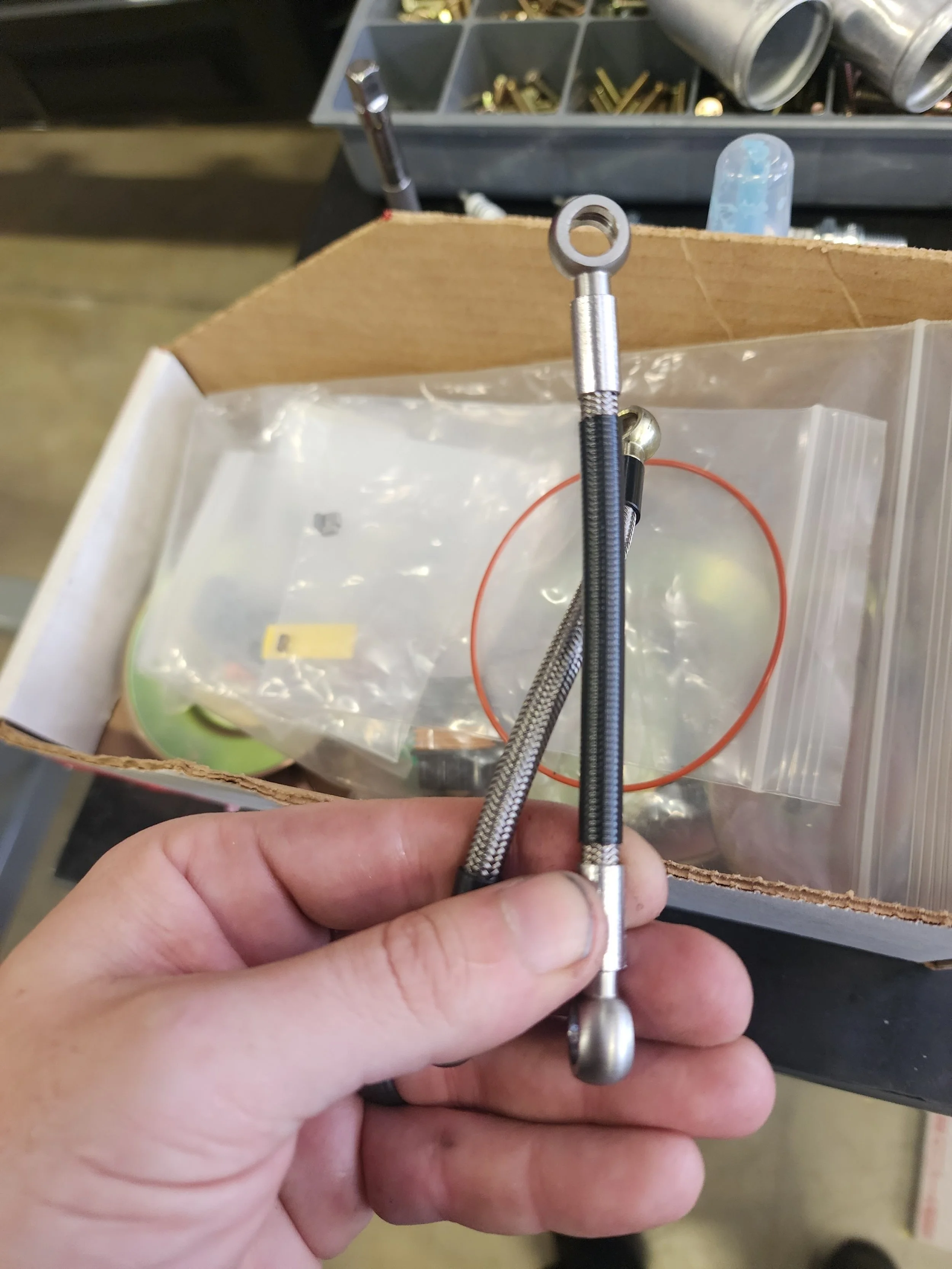

Uprated oil lines, Brown and Miller Racing

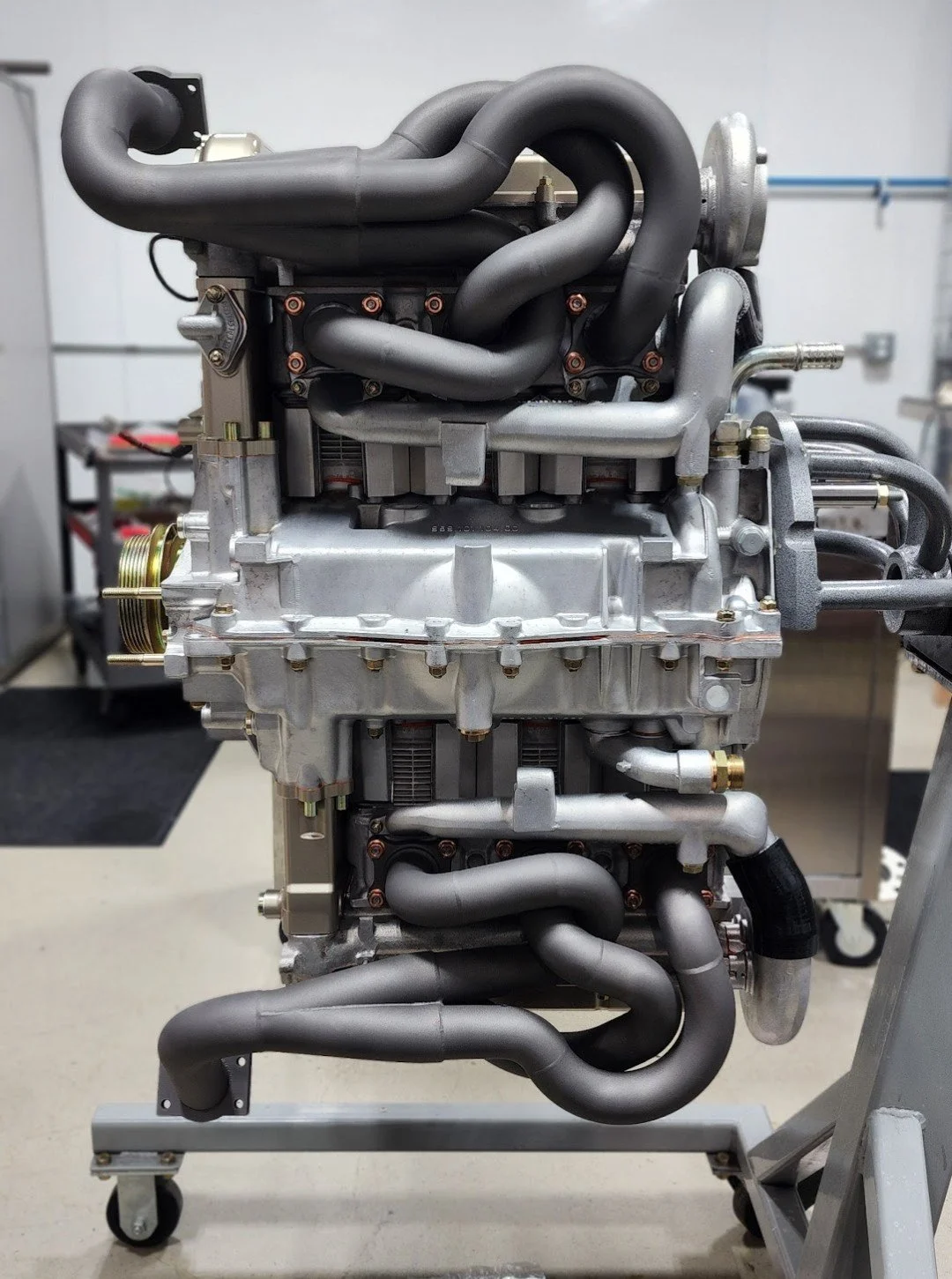

Custom Titanium Headers made by Drake(Olympiccustoms) - Cerakote done for extra heat control

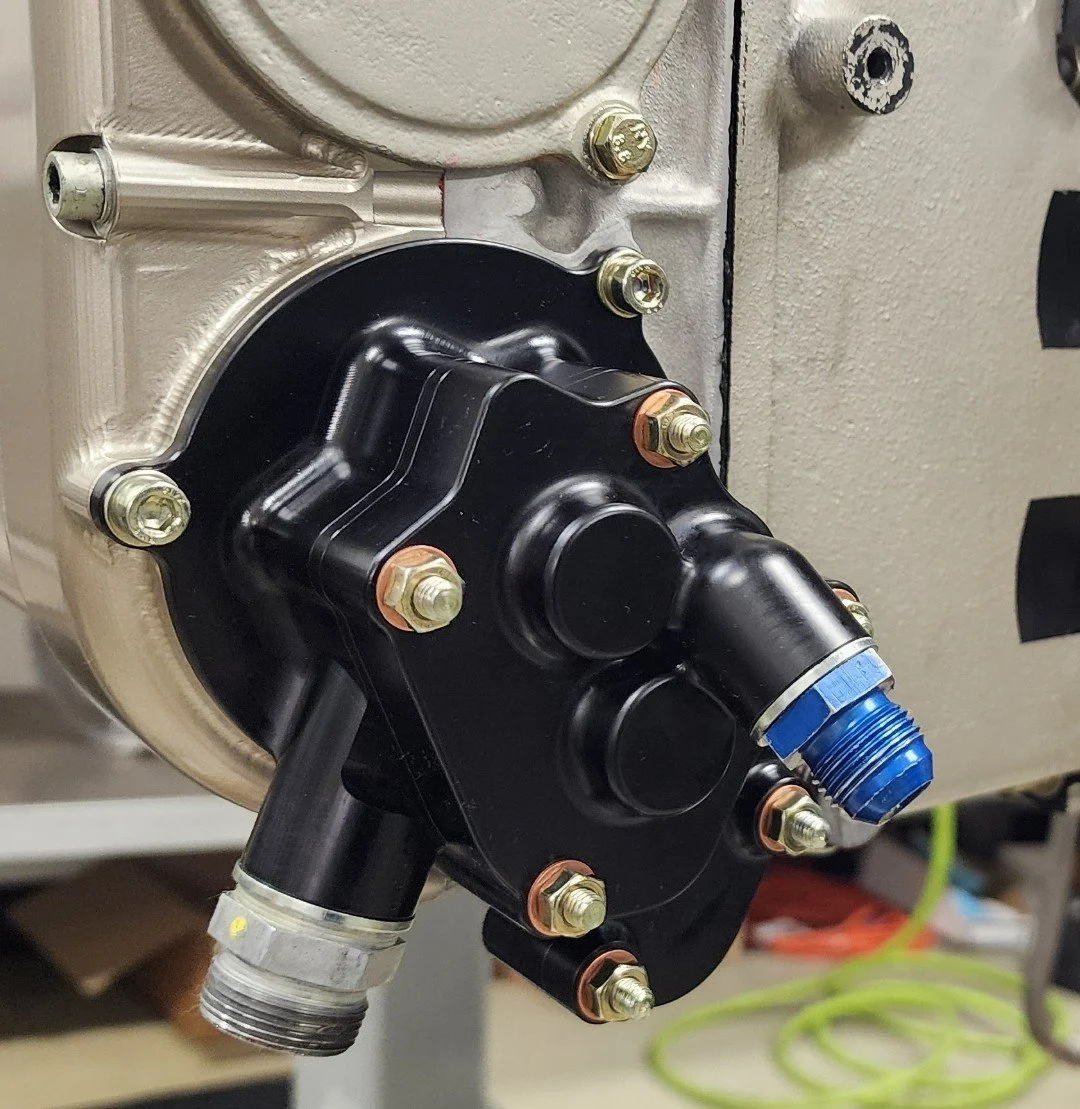

New billet scavenge pump

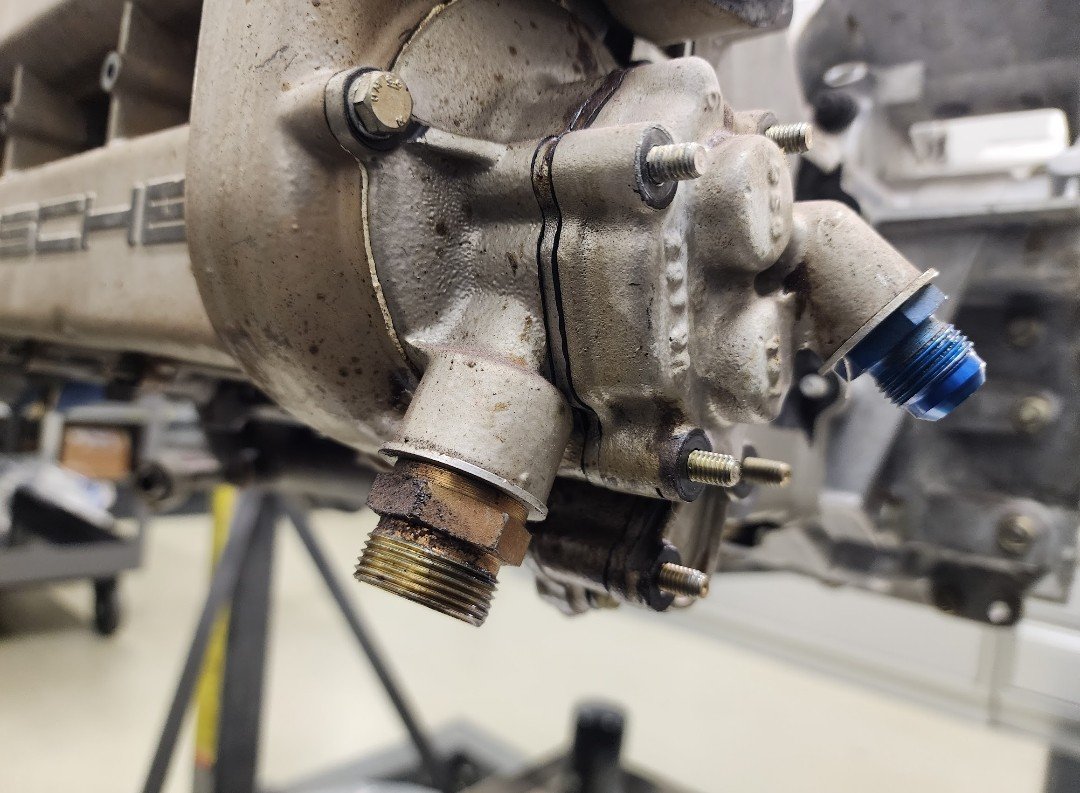

old leaky scavenge pump

Borgwarner’s EFR turbos

Chain housing upgrade